- #Autodesk inventor 2014 sheet metal how to

- #Autodesk inventor 2014 sheet metal generator

- #Autodesk inventor 2014 sheet metal professional

Give it a try! It’s worked pretty well for me so far. Available for SOLIDWORKS, Inventor, Creo, CATIA, Solid Edge, autoCAD. The Sheet Metal Deefaults Screen confirming the detected thicknessīeyond that, there’s not much left to do but carry on! The sheet metal thickness is measured, and now you can begin using your sheet metal tools!

#Autodesk inventor 2014 sheet metal generator

You’ll also use the Frame Generator to create structures housed in sheet metal.

#Autodesk inventor 2014 sheet metal how to

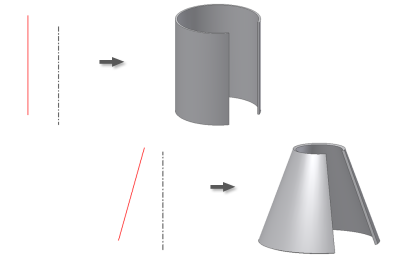

You’ll learn how to use all the sheet metal commands, how to assure your models unfold, and how to create custom punches. Once you select the base face, Inventor will open the Sheet Metal Defaults dialog box, and display the thickness as measured in the Thickness field. Autodesk Inventor 2014: Sheet Metal Design expands your modeling skills for both sheet metal and standard parts. This is what will help Inventor find the sheet metal thickness for you. This face represents the face that Inventor is going to unfold around. Starting with a model that needs to be converted to sheet metal.įirst, it’s converted to sheet metal with the Convert to Sheet Metal icon.Īfter selecting this icon, Inventor is going to ask you to select a base face. What’s new in Autodesk Inventor 2016- How to automatically detect the material thickness in sheet metal It’s currently a “standard” Inventor part, and hasn’t been turned into a sheet metal component. That is, to create and edit sheet metal parts, generate flat patterns, and document the designs in drawings. The structure of the training course follows the typical stages of using the Autodesk Inventor software. In my test, I used a base solid, as you might see in an imported file. Autodesk Inventor: Sheet Metal Design Training This course on Sheet Metal design teaches design concepts and techniques such as flanges, contour rolls, hems, folds, rips, bends, corner rounds/chamfers, where you can design sheet metal parts and multi-body parts, turn them into flat patterns for drawings and manufacturing. sheet metal modeling with the Autodesk Inventor software. The process starts out with a part in the Inventor part modeling environment. For bending operations, certain things are not allowed. Check at the bottom of this post for the video version of this blog, or just keep on reading for the text version! Chapter 11 Working with Sheet Metal Parts Sheet metal fabrication follows rules. If you delete the flat pattern, the drawing also loses the flat pattern view.In short, when converting a model to sheet metal, Inventor 2016 automatically detects the material thickness, versus the “measure and copy” method of previous Inventor versions. The flat pattern must be created in the part before you can place a flat pattern view in the drawing. Mastering Autodesk Inventor 2014Deskripsi lengkap. freeform modeling, Convergent Modeling, sheet metal design. Autodesk Inventor and Sheet Metal Manufacturing From Drawing to Fabrication. The Drawing Manager uses the flat pattern for the flat pattern view. NX CAM is at the forefront of Siemens strategy, and in collaboration with Sandvik Coromant. Sketched and placed features can have unpredictable results, so use Punch Tool to add these shapes to your sheet metal part. Optionally, they can be represented using a selected sketch or with a center mark.

#Autodesk inventor 2014 sheet metal professional

SOLIDWORKS Professional Advanced Preparation Material (SOLIDWORKS 2021): Sheet Metal, Weldments. Total project time approximately 20 minutes. AutoDesk Inventor 2017 : 13 : Stress Analysis. If these features are placed onto sheet metal faces using the Punch Tool command, they are accurately represented as 3D features on the flat pattern. In this project, we’ll design a bracket using the sheet metal environment inside Inventor for an inkjet printer, while in-context of the larger assembly. 3) Roof Curb Minimum Height: This will Metal Roof Panel Revit Families. Code: 65-34-33: NBS Reference Description: Generator Sets: CSI MasterFormat 2014 Code: 26 32 13. The minimum weight for copper sheets used in flashing roof penetrations is 16 oz. Select Edit Flat Pattern Definition from the context menu when the Flat Pattern node is selected to modify orientation, punch representation and bend angle measuring options.įeatures that require material deformation, such as louvers or dimples, cannot be flattened. How to Show Multiple Sheet Numbers in the Title Block. The flat pattern is typically created normal to your initially sketched face feature however there may be times when you must adjust the orientation. However, these edits are not visible when the model returns to the folded state. Edits can be made to the flat pattern that simplify subsequent manufacturing operations. The flat pattern updates automatically when you edit the 3D model.

The part browser displays a Flat Pattern node and the flattened state of the model is displayed when this node is active. Create Flat Pattern calculates the material and layout required to flatten a 3D sheet metal model.

0 kommentar(er)

0 kommentar(er)